We are architects for a better future.

We create buildings that are radical in approach but sensitive in context, to get people talking and speed up change. We challenge the norms to create a better future for us all - you, the community, the planet, and our future together.

About us

We are targeting all of our new builds to be Whole Life Zero Carbon by 2025

What do the recent changes to the National Planning Policy Framework (NPPF) mean for your new home?

Your journey towards a healthier, more joyful home starts here

Our modular construction system is designed to make building easier and more sustainable for you

No Building As Usual: Our student live build education programme

We're delighted to be shortlisted for three categories in this year's Archiboo Awards: the Activism award, Best Written Content award, and Best Use of Video award in collaboration with Jim Stephenson. Explore the awards shortlists at the link.

We have won planning permission for a ‘whole-life zero-carbon home’ in rural Cambridgeshire, next to a 15th-century moated manor house The low-impact home, designed for a ‘forward-thinking’ family of four, will occupy a post-war barn, centring around a full-height planted atrium space designed to enable passive heating and cooling.

We've been shortlisted to design a new and vibrant neighbourhood in Wolverhampton for Capital & Centric, alongside many exciting and progressive names in the industry. We're excited to be collaborating with Metropolitan Workshop and Mole Architects on the competition.

Our project Breach House was recently granted planning permission for an ‘exemplary’ water-powered home in rural Leicestershire. You can read about it now in the Architects' Journal.

Breach House is a home inspired by the water that surrounds it, and designed for climate resilience. It was granted planning permission in February 2024 under Paragraph 84 of the NPPF.

We worked with students from the University of East London to devise a roof-supporting column with otherwise unusable timber at one of our sites within ancient English woodland.

Looking to avoid high energy bills, lengthy mortgages and other people? Tim Dodd features Nest House in the BBC's recent piece on off-grid living.

At the end of December 2023 the NPPF was updated meaning yet another rebrand for exception clauses Paragraph 80 and Paragraph 134. Paragraph 80 is now Paragraph 84, and Paragraph 134 is now Paragraph 139. The good news for you (and for us!) is that there are no changes to the wording or content of either clause.

A feat of engineering that provides a haven for natural reflection in Leeds City Centre to ‘make a stand’ against wasteful supply chains.

The screenwriter’s retreat, a garden studio built for creativity using hand-crafted sustainable materials.

Studio Bark's research and findings relating to Paragraph 84 of the NPPF (previously Paragraph 80).

In 2021 we launched ‘No Building As Usual’ as a highly collaborative cross-sector approach to student builds.

Visit our Studio page to find out more about who we are and what we stand for at Studio Bark.

A bespoke lodge in the Norfolk countryside, built by students using traditional local materials.

Periscope House is the story of a harmonious and collaborative client-architect relationship. We were able to create an affordable, environmentally exceptional home that provided the family with permanence, comfort, and a connection to nature.

Studio Bark's research and findings relating to Paragraph 139 of the NPPF (previously Paragraph 134).

Nest House is a single-storey eco-home, designed to respond to the client’s specific accessibility needs. Constructed using Studio Bark’s modular and demountable U-Build system, the house delivers on their dreams for a low carbon eco-home that celebrates the surrounding countryside.

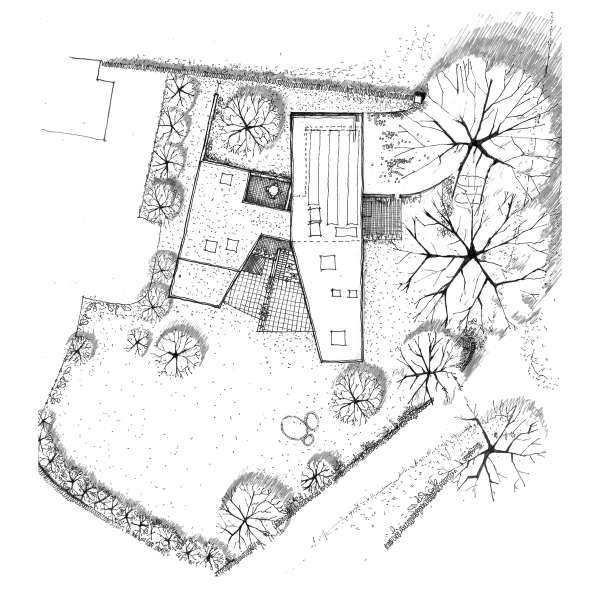

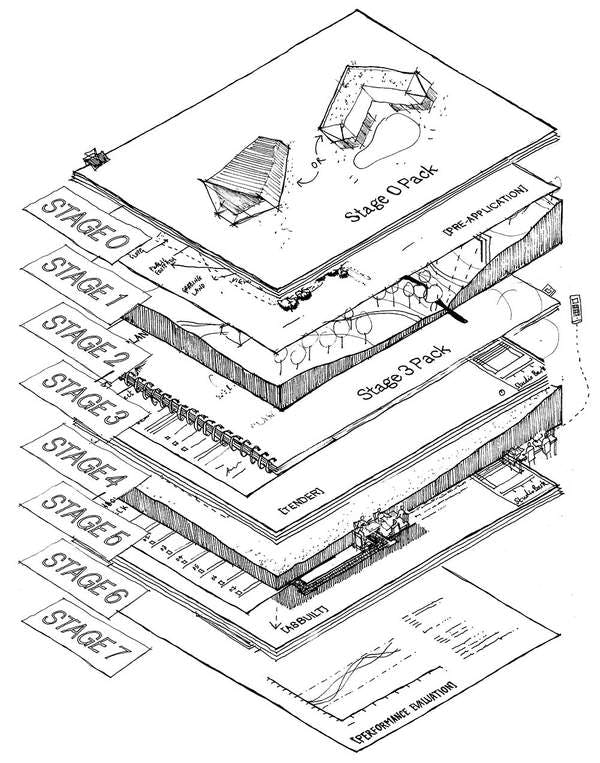

The Bark Journey is designed to give you an overview of our process. We use the RIBA Plan of Work to move through the stages from project briefing through to building completion.

Sun House is a Paragraph 84 (previously Paragraph 80) home which builds on a history of solar house design to deliver our clients a beautiful, warm and bright home. The house could be a new prototype for climate resilient architecture; a home which builds upon the principles of the Grade II listed home the clients currently live in, but incorporating modern technologies to ensure light, bright connected spaces which have both low embodied and operational carbon demands.

We developed U-Build to transform the way people think about buildings and the way they are built, by simplifying the construction process and enabling anyone to participate.

Measuring only four-and-a-half metres across and three metres deep, this small new space does much to enhance the Victorian mid-terraced house. A large fixed skylight, paired with full-height glazed French doors, fills the wooden box extension with natural light and lends much to its Victorian host.

The Hood was created in collaboration with artist Michael Pinsky whose work is known for challenging the status quo on climate change, urban design and societal wellbeing.

Our how-to guide reveals the different types of survey you may need before building a new home on your land.

We worked with Chris and Roxie to construct their home with a team of architecture students in a pioneering live build using Studio Bark’s innovative U-Build construction system.

Cork is a common interior floor finish, and has even been used as external rainscreen cladding. We set ourselves the task of building an entire building from cork to see if it would work as the sole material, eliminating the need for frames, linings, glues, tapes, breather membranes and wet trades.

Our clients built their own garden pod - and you can too. Manbey Pod is a garden studio designed as a family amenity space, storage area and textile studio. This was the first time we’ve handed over the U-Build construction to the clients, Peter and Joan.

Oolite House is a family home nestled into the western escarpment of the Cotswold Hills. The topography and surrounding grain have shaped the form and massing to ensure the house sits comfortably within its context. The landscape and house are intertwined, bringing family life into immediate contact with the natural world outside.

Explore

We're up for THREE categories in the Archiboo 2024 Awards

Planning permission granted! A low-impact eco-home on the grounds of a derelict post-war steel barn

Studio Bark shortlisted for Wolverhampton neighbourhood by Capital & Centric

Breach House "water-powered home" features in the AJ

Planning permission granted! A Paragraph 84 home inspired by water and designed for climate resilience

Studio Bark in Dezeen: Utilising waste timber with students from the University of East London

Read about off-grid living at Nest House in the BBC

What do the recent changes to the NPPF mean for your Paragraph 80 or Paragraph 134 home?

What are we Making A Stand about?

The exploratory process behind Holloway Lightbox

Building in isolated locations in the countryside with Paragraph 84

How can we better equip the next generation of architecture students?

Meet the Barkers

An idyllic lodge built by students

Our first Grand Design, Periscope House

Paragraph 139: A new route to gaining planning permission in the countryside?

A single storey eco-home maximises accessibility and comfort Francine and Stephen

The Bark Journey, designed for you

Could solar house design provide you with a warm, bright, zero carbon home?

U-Build: Our sustainable construction system for the future

A low impact extension that drastically enhances the client's living space

Challenging the status quo on climate change with artist Michael Pinsky

What surveys do I need for a new home on my land?

A self-build project for first time buyers

An entire building made from cork?

Peter and Joan's self-build journey